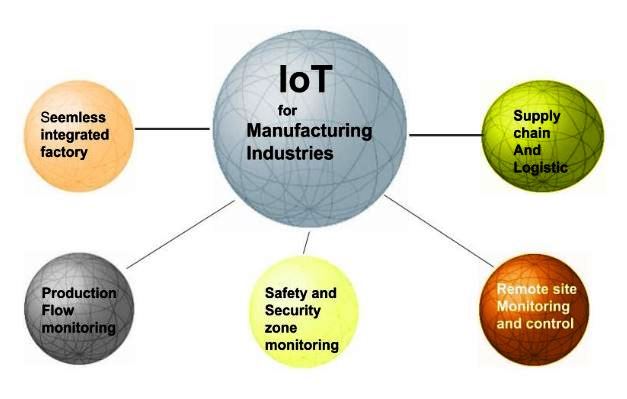

A smart factory via IoT

A smart factory is a futuristic approach to the traditional factory concept where all the decisions, operations and the manufacturing related activities would be performed using robots, Internet of Things (IOT) and the intelligent systems having proficient command on the inside and outside environment.

According to Bernard Marr, a factory is considered as the ‘smart factory’ only if it possesses following characteristic features –

Interoperability – The connectivity between man and machines that are capable of communicating with one another.

Transparent information flow – This is achieved by creating a virtual copy of the real or physical world data in the sensor based information system. It helps in the realistic assessment of information and hence time sensitive decision making and implementation of production strategies.

Guided by technology – Such technology becomes the right hand for human beings in tasks where huge production at great speed is required. The technological advancement also plays a crucial role in scenarios where tasks considered unsafe or hazardous for human beings are skillfully performed by intelligent robots with excellent level of accuracy.

Application of digital twins in the real world (Automation and IoT)

The internet has become an integral part of the overall business industry. There is no sector or business which is left out of the digital era. With advancements taking place on almost a daily basis, the next big thing that is happening and trending is the digital twin technology.

The power of decision making – The autonomous decision making capability of intelligent machines is making product development a hassle free task. Without having to wait for minor decisions from one prime source, these systems are capable of performing tasks, self-analyzing scenarios and making the much needed corrections.

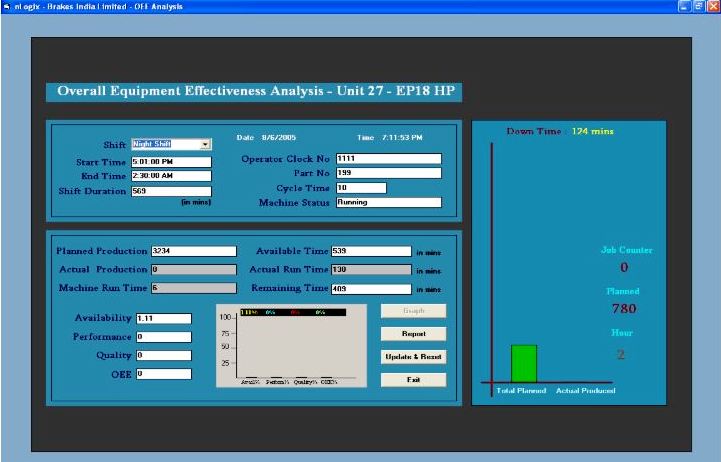

In a smart factory, the industrial verticals will be connected closely with one another and the management of various production steps right from the product development to the supply chain management will be done through correlated systems that have the intelligence to perform tasks just like humans, even way better than them. Following processes would be interconnected to deliver a seamless operational execution –

- Planning and production in the factory

- Development of the specific product

- Logistics

- Enterprise resource planning (ERP)

- Manufacturing Execution Systems

- Controlling Techniques

- Sensors and actuators in the industrial field