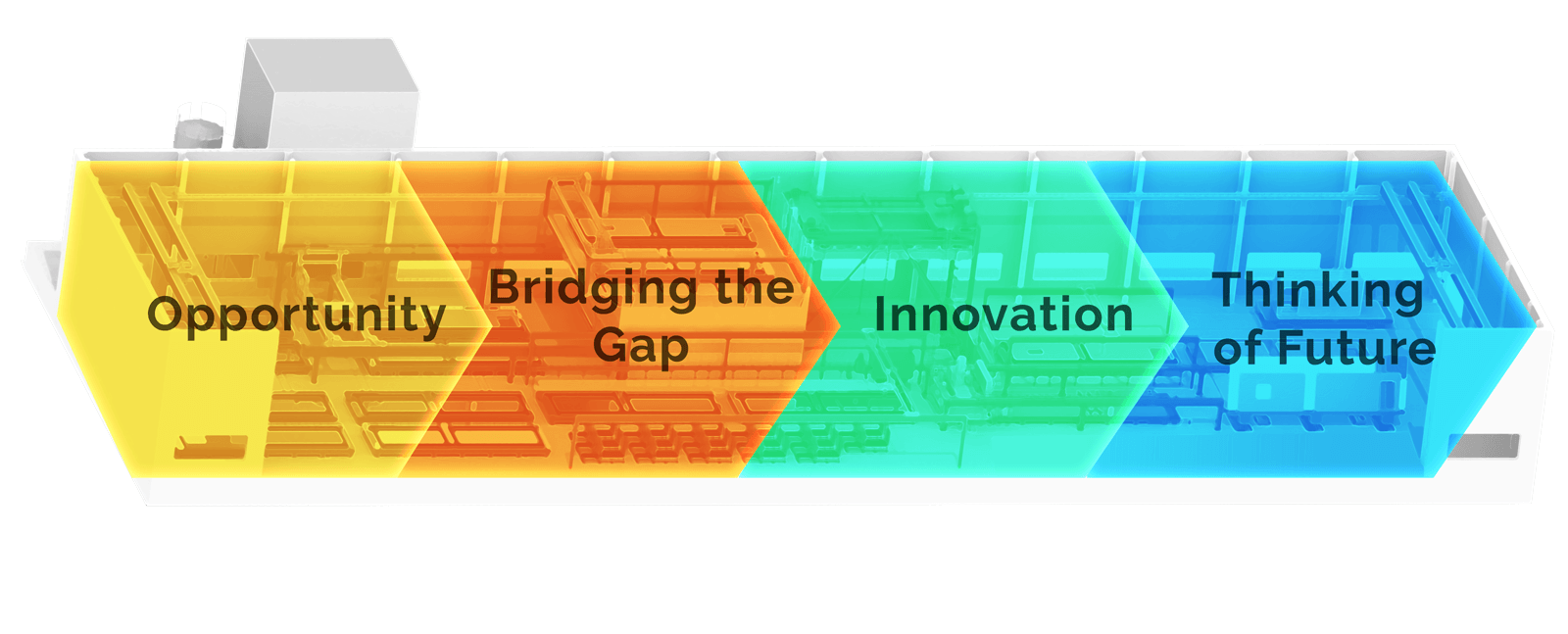

The production is highly energy intensive .Cost effectiveness of production is based on monitoring and controlling of each process control in all units from feeding of Iron ore & coal feeding into a reactor, melting, and formation and rolling to finished products.