Casting is one of the most important and major processes of manufacturing industry. Pouring molten metal into mould and getting out exact shape of the article or component in all through manufacturing process involves challenges of safety hazards to human beings, especially when hot metal and alloys are handled and also produce some environmental problems.

Casting is used to produce an average of about

Factors contributing to harsh environment in foundry industries are Blistering temperatures, metallic dust, and molten materials.

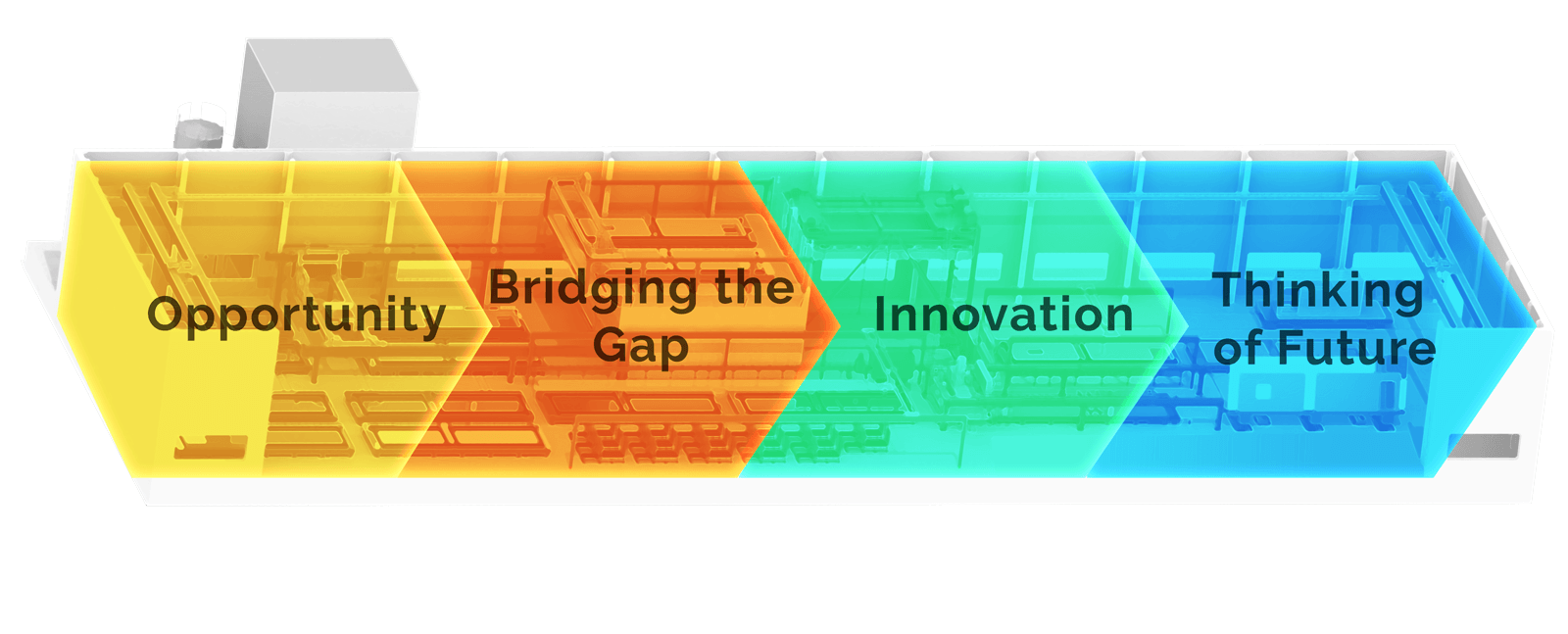

Opportunities for mechanization and automation in the foundry industry increased significantly.

With technology, Foundry industry is now getting connected end – end.

For many years, the data pertaining to the composition of the melting material was entered manually into a PC, which made precise production planning and tracking and tracing difficult is not being fully automated with RFID creating relationship and making the tracking of the mould process easy.

Robotics automation to handle challenges of Dirt - Hot -Heavy – hazardous.

It leads to high productivity, flexibility, consistency in quality, access in difficult areas and a relief from fatigue & health hazards.

These factors have also helped to keep foundries on the forward edge of the automation frontier.

Our expertise and our team ability to identify opportunities in the production give us the ability to deliver automation solutions meeting Industry 4.0.